In the realm of efficient control systems, choosing the right Motorized Valve can make a significant difference. Renowned expert John Smith once stated, “The right valve is vital for optimizing system performance.” His insights underline the importance of selecting quality components for operational success.

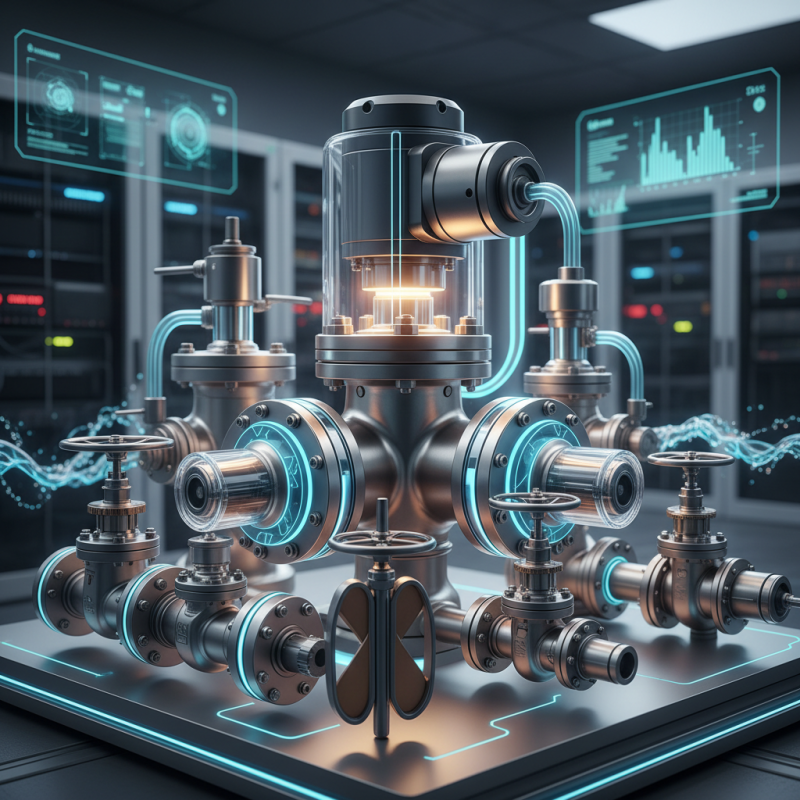

Motorized Valves offer precise control over fluid flow. They enhance automation and improve energy efficiency. In industries ranging from HVAC to process manufacturing, they play a critical role. Many models exist, but not all perform equally. Some valves may fail under pressure or leak over time.

The challenge lies in identifying the best options. Each system has unique requirements. Users must consider factors like size, material, and actuator type. A poor choice can lead to operational inefficiencies or increased costs. Reflecting on these issues can guide buyers to make informed decisions. As John Smith emphasized, the right choice matters immensely in achieving system efficiency.

Motorized valves play a crucial role in modern control systems. They are designed to regulate the flow of liquids and gases. According to a recent industry report, the demand for these components is projected to grow by 8% annually until 2026. This growth reflects a rising need for efficiency in various applications and sectors.

The operational efficiency they provide is significant. For instance, motorized valves can respond quickly to system changes, minimizing downtime. An estimation suggests that over 30% of energy costs in industrial settings can be saved by utilizing advanced control systems that incorporate these valves. However, not all systems achieve optimal functionality. Frequent maintenance issues can arise, leading to inefficiencies.

Not all elected valves perform equally. Some systems may struggle with precision and reliability. The technology used in motorized valves varies widely, impacting performance. It’s essential to evaluate specific application requirements when selecting valves. Balancing cost-effectiveness with reliability remains a challenge for many industries. Reports indicate that user errors in selection lead to unforeseen complications, emphasizing the need for careful planning.

| Type | Actuation Method | Nominal Size (inches) | Flow Coefficient (Cv) | Material | Voltage (V) | Response Time (sec) |

|---|---|---|---|---|---|---|

| Ball Valve | Electric | 1 | 25 | Brass | 24 | 5 |

| Globe Valve | Pneumatic | 2 | 40 | Stainless Steel | 120 | 8 |

| Butterfly Valve | Electric | 3 | 50 | PVC | 230 | 6 |

| Check Valve | Hydraulic | 1.5 | 30 | Aluminum | 24 | 3 |

| Solenoid Valve | Electric | 0.5 | 15 | Nylon | 12 | 2 |

Motorized valves are essential for effective control systems across various industries. When selecting the best motorized valves, several key features should be prioritized. First, consider the valve's response time. Faster valves improve efficiency, especially in critical applications. A report by the International Society of Automation suggests that valves with a response time of less than 2 seconds can enhance overall system performance by 30%.

Another important aspect is the material used in the valve construction. High-quality materials resist corrosion and wear, ensuring longevity. A study by the Valves Manufacturers Association indicates that valves made from stainless steel last 25% longer than those made from standard materials. This durability is essential in automotive and chemical processing industries where reliability is paramount.

Integration capabilities also matter significantly. Smart motorized valves that enable remote monitoring cater to the demands of modern automation systems. They're becoming a necessity. However, not all systems support seamless integration, which can lead to operational challenges. While the potential for enhanced control is evident, organizations must carefully evaluate compatibility with existing systems. Failure to do so may lead to inefficient operations and increased costs.

In 2026, selecting the right motorized valves is crucial for any efficient control system. Research indicates that the global market for motorized valves is projected to reach $5 billion by 2026. This growth reflects the rising demand across various sectors, such as HVAC, water treatment, and industrial automation. However, not all options excel for every application.

Key features to consider include torque specifications, response time, and durability. A recent study mentioned that improperly selected valves can lead to a 25% increase in operational inefficiencies. Among top contenders in the market, models with a quick response time of under 5 seconds are favored for tight control systems. Yet, some models may not perform well under extreme conditions, which could lead to failures.

Some brands focus on user-friendly designs. They prioritize easy installations and maintenance. Yet, this often comes at the cost of advanced features. Users must weigh their priorities. Balancing cost with performance remains a challenge. The ideal motorized valve may not exist for every specific need. It’s essential to analyze operational demands thoroughly.

Motorized valves play a crucial role in various industries. Their use spans from water treatment to HVAC systems. These valves allow for precise control of fluid flow. This precision helps enhance energy efficiency. In pharmaceuticals, motorized valves maintain sterilization and product quality. Each process requires strict adherence to safety standards, making these valves indispensable.

In manufacturing, motorized valves regulate the flow of materials. This automation reduces human error and increases productivity. However, these systems are not without challenges. Occasionally, improper calibration can lead to flow inconsistencies. Regular maintenance is necessary to prevent failures.

Food processing also benefits from motorized valves. They help control temperatures during cooking and cooling. A small error can spoil the product, affecting quality and safety. Thus, consistent monitoring is essential. While motorized valves offer many advantages, industries must remain vigilant. Small issues can have significant impacts.

Motorized valves are crucial for efficient control systems in various industries. However, maintaining their optimal performance is often overlooked. Regular maintenance can enhance valve longevity and efficiency. According to a recent industry report, 30% of operational issues stem from improper valve maintenance.

To ensure motorized valves function correctly, inspect them regularly. Pay attention to leaks or unusual noises. Clean the valves to prevent buildup that could hinder performance. A simple cleaning routine can significantly extend the valve's lifespan.

Consider scheduling maintenance every six months. This allows for thorough checks and tuning. Replace worn-out components promptly. Misjudged maintenance intervals can lead to unexpected failures. It's a common mistake that can be easily avoided. Remember, a little effort now ensures smoother operations later.

This chart compares the performance metrics of different motorized valves, focusing on flow rate, response time, and energy efficiency. Each metric is vital for selecting the right valve for efficient control systems.