The Center Bearing plays a crucial role in automotive engineering. It supports the drive shaft and ensures smooth rotation between components. According to a recent report by the Automotive Engineering Association, nearly 15% of drivetrain issues arise from faulty Center Bearings. This statistic highlights their importance in vehicle performance and reliability.

Expert James Parker, a renowned engineer in the automotive sector, states, “A well-functioning Center Bearing is vital for the longevity of the drivetrain.” His insights remind us of the intricate balance required within automotive systems. Despite advances, many vehicles still face issues related to wear and tear of the Center Bearing. It’s a challenge that needs to be addressed more effectively. Regular maintenance is often overlooked, leading to premature failures.

The quality of a Center Bearing can directly affect vehicle safety. Many drivers may not realize the impact of this component until it's too late. Understanding its function can prevent unexpected breakdowns and improve overall driving experiences. Awareness and education around Center Bearings could significantly enhance vehicle longevity and safety on the road.

Center bearings play a crucial role in various mechanical systems. They support rotating shafts, ensuring smooth operation. By maintaining alignment, they prevent excessive wear and tear. Without them, machinery can face significant issues. Over time, misalignment may lead to component failure.

The importance of center bearings extends beyond mere support. They contribute to the overall efficiency of machines. Properly functioning center bearings minimize vibrations. This, in turn, reduces energy consumption. The quality of a center bearing can directly influence a machine's lifespan. However, many overlook them during maintenance checks, which can be detrimental.

Issues with center bearings often go unnoticed. Symptoms like unusual noises or vibrations may indicate problems. Regular inspections are essential, but they are frequently neglected. Understanding their role enhances reliability and performance, yet many remain unaware. Reflecting on the importance of these components can lead to better machinery management.

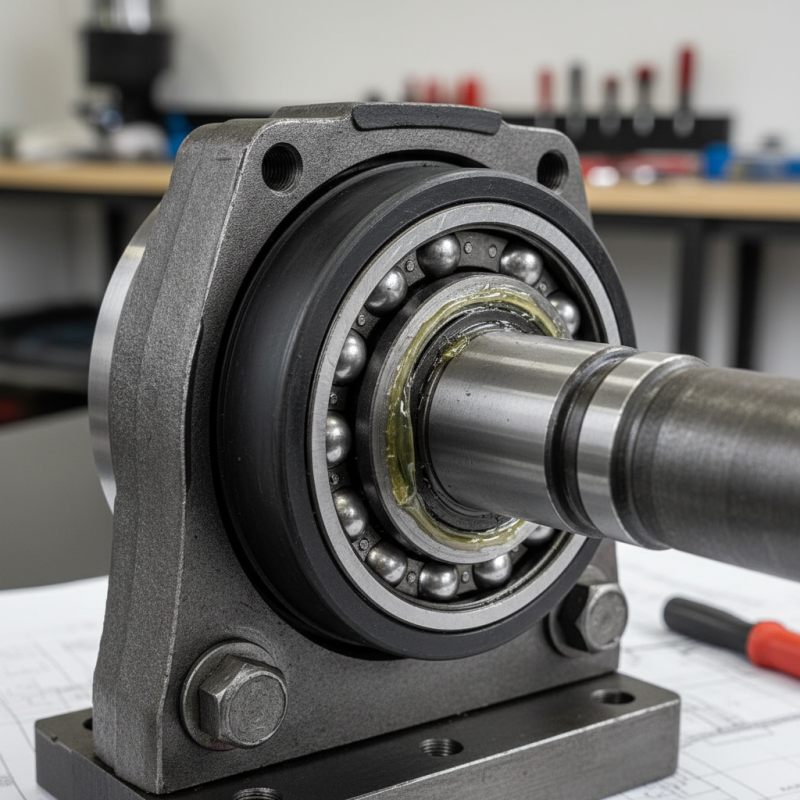

The center bearing is crucial in transferring loads between different components. Its structure often includes a housing, a bearing element, and a sealing mechanism. The housing is typically made from durable metals or reinforced plastics. This choice ensures strength and longevity. The bearing element, which might be a ball or roller setup, allows smooth rotation. It reduces friction and wear, essential for efficient operation.

Materials play a pivotal role in the performance of center bearings. High-quality steel is often preferred for the bearing elements due to its resistance to deformation. Some designs incorporate synthetic materials to decrease weight, enhancing fuel efficiency. Seals often use rubber compounds to keep contaminants out. However, the effectiveness of these materials can vary. Over time, wear and environmental factors may compromise their integrity.

The design of a center bearing can be complex. Engineers often optimize shapes and material blends for specific applications. Yet, not every solution is perfect. Sometimes, using cheaper materials leads to quicker failures. It’s essential for designers to balance cost and performance carefully. Understanding these components deepens awareness of why regular maintenance is vital.

Center bearings play a crucial role in the stability of a vehicle's drive system. These components support the driveshaft, helping to transmit torque efficiently from the transmission to the rear axle. Understanding how they function requires looking into their operational principles.

Center bearings operate by providing a pivot point for the driveshaft. When the vehicle moves, the driveshaft rotates, and the center bearing absorbs vibrations. This process reduces stress on other components, which ultimately enhances performance. According to industry reports, a well-maintained center bearing can improve torque transmission efficiency by up to 15%. This means smoother rides and improved fuel economy.

Tips: Regular inspections are essential. Look for signs of wear and tear on the bearing. If you notice unusual vibrations, it may be time for a replacement. Remember, even minor issues can lead to significant problems if ignored.

In practice, many users overlook the importance of center bearings. They might focus on larger components like engines. Yet, neglecting these smaller parts can lead to misalignment. This misalignment can increase wear on the driveshaft, potentially costing more for repairs. Awareness and timely maintenance are keys to ensuring longevity in your vehicle’s performance.

Center bearings play a crucial role in various industries. They support rotating shafts, ensuring stability and reducing vibrations. This leads to enhanced efficiency and prolonged equipment life. According to a recent market analysis, the global demand for center bearings in the automotive sector is expected to grow by 5.6% annually through 2025. This data reflects a strong trend towards optimizing vehicle performance.

In the manufacturing sector, center bearings are used in conveyors and heavy machinery. They help minimize wear and tear in high-speed applications. A report highlights that 33% of machinery failures are linked to inadequate bearings. This signifies a need for better preventive measures and regular maintenance systems. Operational downtime can be costly; thus, investing in quality center bearings is critical.

The aerospace industry also benefits from center bearings. They provide stability in aircraft components, crucial for safety and reliability. A study found that 40% of aircraft incidents relate to mechanical failures. This emphasizes the importance of quality control in bearing applications. While advancements in technology improve designs, the need for rigorous testing and feedback remains fundamental.

Center bearings play a significant role in a vehicle's drivetrain. These components allow for smooth rotation during movement. However, over time, they can face issues that lead to performance problems. It’s essential to be aware of common center bearing issues to ensure a reliable driving experience.

Vibrations are a common problem. When the center bearing wears out, it may lead to noticeable vibrations, especially at higher speeds. This can disturb the driver and passengers. Regular inspections can help identify these vibrations early.

Another concern is noise. A failing center bearing can produce strange sounds while driving. These noises can indicate that the bearing needs immediate attention.

Maintaining center bearings is crucial for vehicle health. Regular lubrication can prevent wear. Inspecting the bearing for signs of rust or dirt is necessary. Cleaning it can extend its lifespan. If issues persist, replacement may be the best solution. Ignoring these signs can lead to more severe problems later on. Regular maintenance can ultimately save time and money in the long run.