Choosing the right Auto Parts Bearings is crucial for vehicle performance and safety. According to industry data, improper bearing selection can lead to a 30% increase in mechanical failure rates. Auto parts bearings are integral in reducing friction and ensuring smooth operation.

Selecting the right bearings requires understanding your vehicle's specifications and usage. Some vehicles run under heavy load, while others face extreme temperatures. This variance directly affects bearing longevity and functionality. The wrong choice can result in noise and vibration, or even accelerate wear on other components.

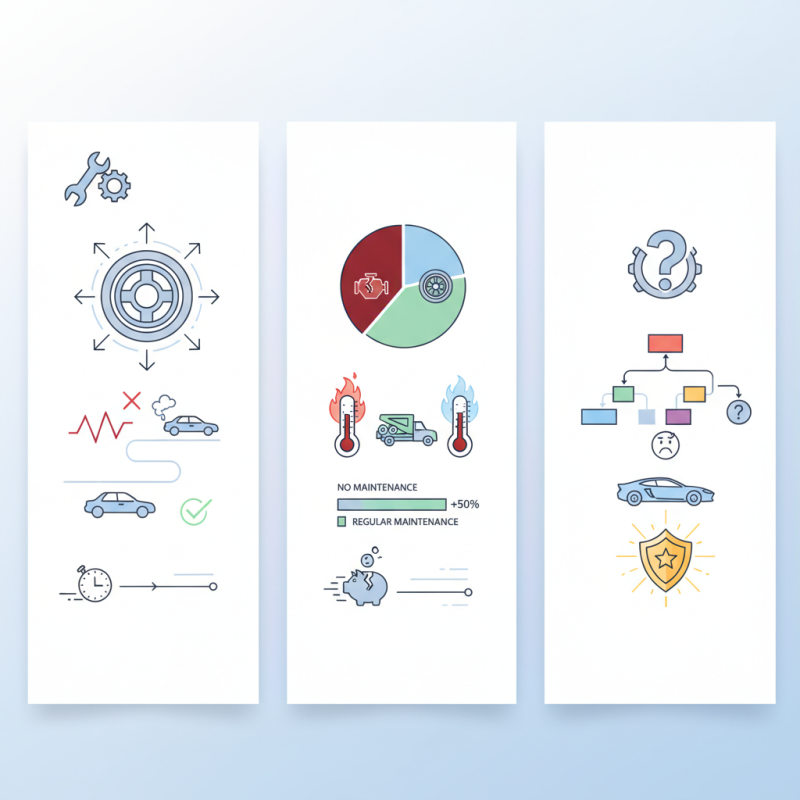

Research suggests that regular maintenance can extend bearing life by up to 50%. However, many drivers overlook this essential aspect. Selecting quality auto parts bearings matters but often, consumers face confusion due to abundant options. Rushing this decision can lead to costly repairs down the line. Each vehicle deserves the best to operate efficiently.

Choosing the right auto parts bearings is crucial for vehicle performance and longevity. Different types of bearings serve specific functions in a vehicle. The most common types include Ball Bearings, roller bearings, and needle bearings. Each type has unique characteristics that impact their performance under various conditions. For instance, ball bearings are versatile and can handle both radial and axial loads. Roller bearings are ideal for heavy loads, while needle bearings offer high load capacity in a compact design.

Industry reports indicate that proper bearing selection can improve vehicle efficiency by 15%. However, many vehicle owners overlook this aspect. According to a survey by a leading automotive industry study, 40% of drivers are unaware of what type of bearings their vehicle uses. This lack of awareness can lead to inadequate replacements and ultimately higher repair costs. It's vital to consider the operating environment and load conditions when selecting bearings.

Using the wrong type of bearing can lead to premature wear and tear. Some vehicle owners might think all bearings are interchangeable, but this is misleading. For example, choosing a non-sealed bearing in a high-moisture environment can lead to failure. Evaluating specifications and applications is necessary for optimal performance. The right choice not only enhances reliability but also ensures safety on the road.

When selecting auto parts bearings, several key factors come into play. The type of vehicle you own is crucial. Different vehicles require different bearings based on weight and usage. For instance, heavy-duty trucks often need robust bearings that can withstand high loads. A report by the American Society of Mechanical Engineers indicates that improper bearing selection can lead to a 30% increase in mechanical failures.

Material also plays a significant role. Bearings are commonly made from steel, ceramics, or composite materials. Steel offers high strength but may wear down faster under certain conditions. Composite materials are lighter and resist corrosion. A study from Automotive Engineering shows that using the wrong material can reduce the lifespan of bearings by up to 50%. This highlights the importance of matching the bearing material to the operating environment.

Bearing size should not be overlooked. Even a slight mismatch can cause significant issues. Too tight a fit can lead to overheating, while a loose fit may result in vibrations. According to industry surveys, nearly 40% of vehicle performance problems are related to bearing specifications. It’s vital to consult your vehicle’s manual for the correct size and specifications. Each of these factors requires careful consideration to ensure optimal performance and durability.

| Bearing Type | Material | Load Capacity (lbs) | Speed Rating (RPM) | Temperature Range (°C) |

|---|---|---|---|---|

| Ball Bearing | Steel | 500 | 30,000 | -20 to 120 |

| Roller Bearing | Chrome Steel | 800 | 20,000 | -30 to 150 |

| Thrust Bearing | Bronze | 300 | 15,000 | -40 to 100 |

| Spherical Bearing | Nylon | 600 | 18,000 | -20 to 90 |

Choosing the right auto parts bearings can be tricky. It’s essential to understand the size and specifications that fit your vehicle. One quick way to start is by checking your owner’s manual. This resource often gives you the exact measurements needed.

You can also measure the bearings directly. Use calipers to check the outer diameter and inner diameter. This process sounds simple but can lead to mistakes. Small discrepancies can lead to performance issues. Pay attention to the tolerances as well. Even a slight variation in size can make a difference.

Additionally, consider the type of material used in the bearing. Different materials have unique benefits and drawbacks. Some might offer better longevity while others provide a smoother motion. Do a bit of research on these materials before making a choice. Reflect on which attributes matter most for your driving needs, and don’t rush the decision. Your vehicle deserves the right parts to ensure safety and performance.

When selecting auto parts bearings, evaluating quality and performance ratings is crucial. Bearings play a significant role in a vehicle’s operation, impacting fuel efficiency and longevity. According to research from the National Institute for Automotive Service Excellence, high-quality bearings can reduce friction and extend service life by up to 30%. This fact highlights their importance in any vehicle's maintenance plan.

Understanding performance ratings helps gauge reliability. Many bearings are rated based on load capacity, speed limits, and durability. A study by the Automotive Engineering Society indicates that bearings designed for higher load capacities often perform better under stress. It’s essential to match these specifications to your vehicle's requirements. However, some ratings may mislead buyers. Always look for independent testing sources. They provide a clearer picture of performance.

Quality materials also matter. Steel is commonly used, but variations exist. Some bearings use ceramic materials, promising lightweight benefits. However, these can come with trade-offs in terms of cost and compatibility. Often, consumers face uncertainty—choosing between price and quality. The right choice requires careful consideration of vehicle specifications and intended use.

When installing auto parts bearings, proper technique is essential. Start by cleaning the housing thoroughly. Any dirt can cause premature wear. Apply a thin layer of grease, ensuring even coverage. This helps with smooth rotation. Be sure to check the orientation before pressing the bearing into place. Simple errors here can lead to serious issues later.

After installation, regular maintenance is critical. Check bearing play periodically. Too much play can indicate wear. Listen for unusual noises as well. They may signal a problem. It’s important not to ignore these sounds. Clean and re-grease your bearings according to manufacturer guidelines. This extends their life significantly. Over time, even the best installations can show signs of neglect. Reflect on your maintenance habits to avoid this.