Die Casting Molds are a vital component in the manufacturing process. As John Smith, an industry expert, once stated, "Quality starts with the mold." This emphasizes the influence Die Casting Molds have on product quality. These molds shape the final product and ensure consistency.

Without high-quality Die Casting Molds, manufacturers face numerous challenges. Flaws can emerge, causing defects in the final pieces. These defects may result in waste, increased costs, and customer dissatisfaction. In today's competitive market, such outcomes are unacceptable.

Investing in premium Die Casting Molds might seem costly, yet the benefits outweigh the expenses. Companies can save in the long run by reducing errors. It's crucial to recognize that the choice of mold impacts not just efficiency but also the overall success of manufacturing processes. Reflecting on this, one must consider if the current mold choices truly meet industry demands.

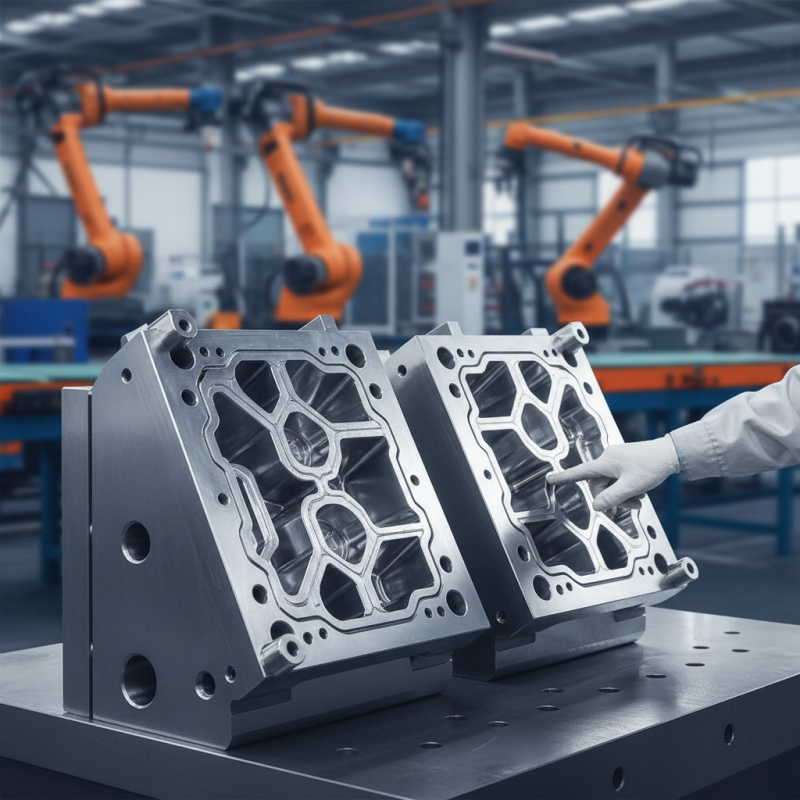

Die casting molds play a vital role in producing precision parts across various industries. They shape molten metal into specific forms, allowing for detailed designs. This process helps create components with tight tolerances. However, achieving that precision is often more complex than it appears.

Maintaining mold quality is crucial for successful outcomes. Molds must be designed to withstand high temperatures and pressure. Over time, wear and tear can affect their performance. Regular inspection is essential to identify potential issues early. If overlooked, flaws in molds can lead to defects in the final product.

Also, the cooling process impacts the accuracy of the part. Inconsistent cooling can cause warping or stress fractures. Engineers must balance speed and quality carefully. Each decision made during the die casting process carries weight. Rethinking strategies and refining techniques can enhance results, ensuring high-quality manufacturing.

Die casting molds play a pivotal role in manufacturing high-quality components. The materials selected for these molds can significantly affect durability and production efficiency. Most molds are made from premium steel and aluminum alloys. Together, they offer high strength and resistance to wear. According to industry reports, steel molds can last up to 10 times longer than aluminum molds in certain applications.

Understanding the properties of materials is crucial. Steel molds tend to have a higher initial cost. However, their longevity can lead to reduced overall production costs over time. Aluminum molds are lighter and easier to machine, but they might not withstand high temperatures as effectively. Therefore, weighing the pros and cons of these materials is essential for manufacturers aiming for quality.

Die casting molds play a crucial role in manufacturing quality products. The design of these molds impacts product accuracy, surface finish, and production efficiency. A report by the Aluminum Association indicates that die casting can achieve tolerances as tight as ±0.005 inches. This precision is essential for industries like automotive and aerospace.

One key factor influencing mold design is the material choice. Most die casting molds are made from steel or aluminum. Steel molds last longer but are costlier. Aluminum molds are lighter and cheaper but may wear out faster. Choosing the right material can affect production consistency and costs. Manufacturers should weigh these options carefully.

Die casting molds are critical for enhancing production efficiency in manufacturing. A recent industry report highlighted that the use of optimized die casting molds can reduce production time by up to 30%. This increase is crucial for meeting market demands and improving overall output. The precision of these molds ensures that parts have minimal defects, minimizing the need for rework.

Efficient design and material selection in die casting molds contribute to lower manufacturing costs. Molds made from advanced materials exhibit better thermal conductivity, which speeds up the cooling process. According to statistical data, improved cooling can elevate production rates significantly. Some molds, however, still face challenges due to wear and tear over time. This can lead to inconsistencies in production, necessitating regular maintenance and updates.

Additionally, not every operation utilizes the best practices for mold design. Many manufacturers overlook the importance of mold maintenance. Reports show that about 20% of production delays stem from mold-related issues. Addressing these aspects can substantially enhance production flow. As technology advances, continuous improvement in mold design remains essential for achieving optimal efficiency in die casting.

Mold maintenance plays a crucial role in die casting. Well-maintained molds lead to high-quality products. When molds are neglected, defects can arise. These include surface imperfections and dimensional errors. Regular inspections are necessary; they help catch issues early. Over time, wear and tear can affect mold performance.

Cleaning molds is essential. Residues can affect the casting quality. Any contamination can lead to poor surface finishes. Operators must be diligent. It’s important to train staff on proper maintenance techniques. A lack of understanding can result in costly errors. Missing small details often has big consequences.

Consider the cooling systems within molds. They need to be monitored closely. Uneven cooling may cause warping in the final product. Addressing these issues promptly is vital. Ignoring them leads to larger problems down the line. A proactive approach can make all the difference. Quality products start with well-maintained molds.